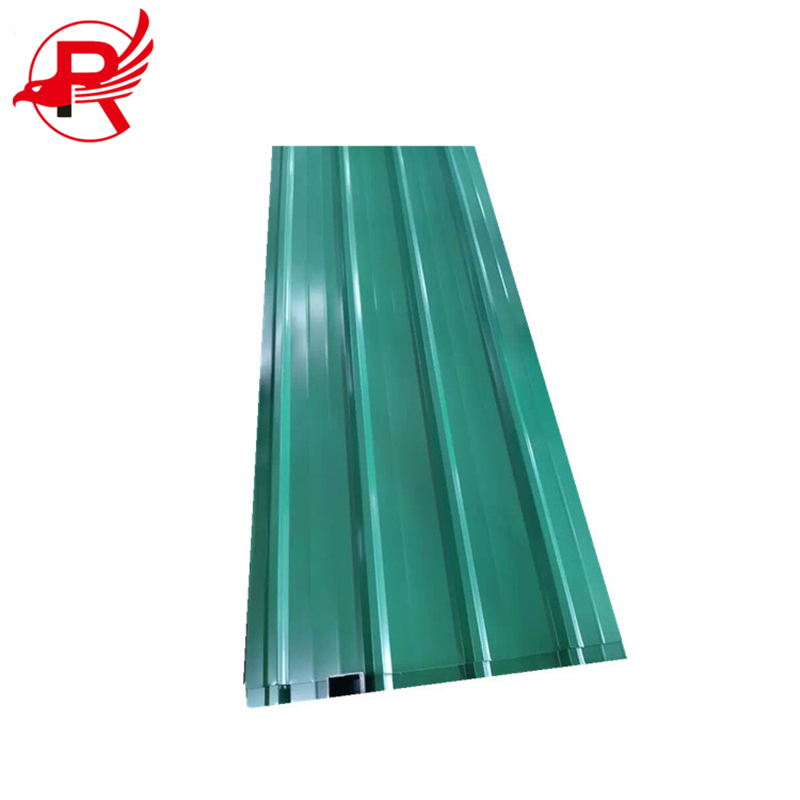

Taflenni Toi Galfanedig wedi'u Gorchuddio â Lliw PPGI SECC Rhychog Cludo Nwyddau Isel

| Safonol | AiSi, ASTM, BS, DIN, GB, JIS |

| Gradd | DX51D/CGCC/SGHC/SPCC/SGCC |

| Rhif Model | Pob Math |

| Techneg | Wedi'i Rholio'n Oer/Wedi'i Rholio'n Boeth |

| Triniaeth Arwyneb | Wedi'i orchuddio |

| Cais | Plât Cynhwysydd |

| Defnydd Arbennig | Plât Dur Cryfder Uchel |

| Lled | 600 - 3600mm neu yn ôl y gofyniad |

| Hyd | 2 - 5 metr |

| Goddefgarwch | ±1% |

| Math | Taflen Ddur, Taflen Ddur Gavalume |

| Gwasanaeth Prosesu | Plygu, Weldio, Datgoilio, Torri, Dyrnu |

| Ardystiad | ISO 9001-2008, CE, BV |

| Gorchudd sinc | 2-275 (g/m2) |

| Dyfnder rhychiog | o 15mm i 18mm |

| Traw | o 75mm i 78mm |

| Sglein | yn ôl Cais Cwsmeriaid |

| Cryfder cynnyrch | 550MPA/yn ôl yr angen |

| Cryfder tynnol | 600MPA/yn ôl yr angen |

| Caledwch | Llawn caled/meddal/yn ôl yr angen |

| Cais | teils toi, tŷ, nenfwd, drws |

Panel tŷ strwythur dur, panel tŷ symudol, ac ati.

Nodyn:

1. Samplu am ddim, sicrwydd ansawdd ôl-werthu 100%, Cefnogi unrhyw ddull talu;

2. Mae pob manyleb arall o bibellau dur carbon crwn ar gael yn ôl eich gofyniad (OEM ac ODM)! Pris ffatri a gewch gan ROYAL GROUP.

Nesaf, byddaf yn cyflwyno perfformiad pob cam cyswllt a phrif nodweddion perfformiad y broses.

1. Dad-goilio plât dur lliw

2. Peiriant gwnïo plât dur lliw

3. Mae'r rholer pwyso yn cywiro arwyneb ceugrwm ac amgrwm y plât sylfaen i wneud wyneb y plât sylfaen yn wastad.

4. Dylai'r peiriant tensiwn sicrhau bod y plât dur yn rhedeg yn esmwyth heb gynnal gwaelod y ffwrnais er mwyn osgoi crafiadau.

5. Mae'r looper dad-weindio yn darparu amser effeithiol a digonol.

6. Gall golchi a dadfrasteru alcalïaidd sicrhau glendid wyneb y bwrdd, sef y sail ar gyfer y broses beintio ddilynol.

7. Mae glanhau yn paratoi ar gyfer gwaith diweddarach ansawdd cynnyrch.

8. Pobwch i baratoi ar gyfer y gorchudd cychwynnol cyntaf.

9. Peintio cychwynnol

10. Sychwch i baratoi ar gyfer y gôt orffen nesaf.

11. Gorffen peintio: yr orsaf hon yw'r orsaf olaf i orffen prif liw paent gorffen plât dur lliw, a chwblhau'r dasg yn unol â gofynion y cwsmer a gofynion cynhyrchu.

12. Sychu: Ar ôl gorffen peintio, bydd y cynnyrch yn mynd i mewn i'r popty sychu i gwblhau prif broses y cynnyrch.

13. Ni ddylai tymheredd oeri'r gwynt fod yn uwch na thymheredd y gwynt; 38 gradd.

14. Rhaid i'r doliwr weindio sicrhau'r amser effeithiol ar gyfer weindio'r weindydd i lawr.

15. Rhaid i'r peiriant gwyndio fodloni gofynion ansawdd ffatri'r diwydiant.

16. Y grym tynnol yw'r grym tynnol a gynhyrchir drwy densiwnu'r platiau rhwng gwahanol rymoedd tynnol.

17. Peiriant cywiro gwyriadau

18. Penderfynir ar y puro yn ôl gofynion wedi'u haddasu gan y prynwr.

19. Gall gwneuthurwr yr argraffydd incjet digidol drin a barnu'r gwrthwynebiad ansawdd yn ôl y wybodaeth incjet, sy'n haws i'w adnabod.

20. Oeri wyneb y plât

21. Winder

22. Defnyddir y raddfa godi i fesur pwysau pob rholyn gorffenedig.

23. Rhaid storio pecynnu platiau dur lliw, warysau ac allforio cynhyrchion gorffenedig yn fertigol.

Mae pecynnu fel arfer yn noeth, rhwymiad gwifren ddur, yn gryf iawn.

Os oes gennych ofynion arbennig, gallwch ddefnyddio pecynnu gwrth-rwd, ac mae'n fwy prydferth.

Cludiant:Cyflym (Dosbarthu Sampl), Awyr, Rheilffordd, Tir, Llongau Môr (FCL neu LCL neu Swmp)

C: Ai gwneuthurwr ua ydyw?

A: Ydym, rydym yn wneuthurwr. Mae gennym ein ffatri ein hunain wedi'i lleoli yn Ninas Tianjin, Tsieina. Heblaw, rydym yn cydweithio â llawer o fentrau sy'n eiddo i'r wladwriaeth, fel BAOSTEEL, SHOUGANG GROUP, SHAGANG GROUP, ac ati.

C: A allaf gael gorchymyn prawf am sawl tunnell yn unig?

A: Wrth gwrs. Gallwn ni gludo'r cargo i chi gyda gwasanaeth LCL. (Llwyth cynhwysydd llai)

C: Os yw'r sampl yn rhad ac am ddim?

A: Sampl am ddim, ond mae'r prynwr yn talu am y cludo nwyddau.

C: Ydych chi'n gyflenwr aur ac yn gwneud sicrwydd masnach?

A: Rydym yn gyflenwr aur saith mlynedd ac yn derbyn sicrwydd masnach.